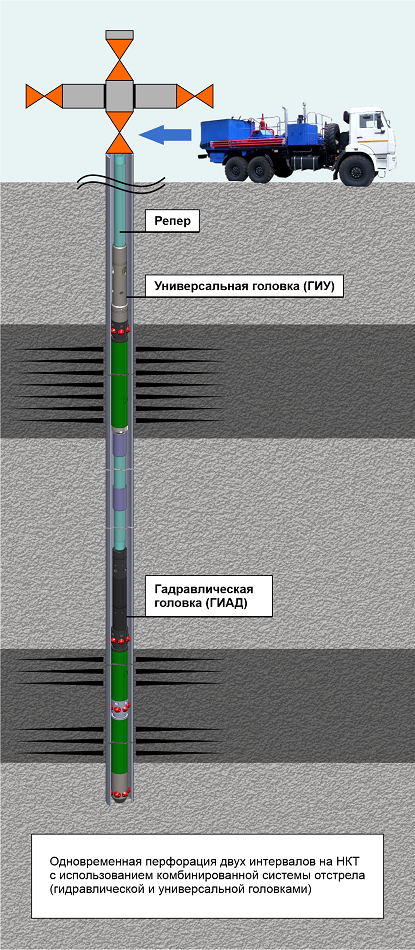

Perforation technology with two initiating heads

DownloadOperating principle

When the lower perforator is triggered, pressure is generated (using the TsA-320 unit) in the annulus. The hydraulic impact socket trips due to the increasing pressure of the liquid on the socket piston - the pins are cut off, the striker initiates the impact detonator, then the perforator is triggered.

Advantages

- The duration of BPO in the well is reduced by the time of one run on tubing, by an average of 1 day.

- The technology allows to save on well-killing fluid and workover costs.

- Perforating in the wells with high formation pressure and with two development objects, as well as sidetracking wells where double density is required

The perforation technology with two initiating heads saves time and increases efficiency. When the lower perforator is triggered, the TsA-320 unit generates pressure directed into the annulus. Increasing fluid pressure on the piston of the impact head initiates its action, which causes impact on the striker and triggering of the perforating gun.

The technology is used when perforating in wells in hydrocarbon fields with increased reservoir pressure and two development areas, as well as in sidetracking wells that require double perforation density.

Technology advantages:

- the time required for BPO is reduced by the period of one tripping operation - on average, the time saving is up to 24 hours;

- resources are saved: less well-killing fluid is used;

- well workover costs are reduced.