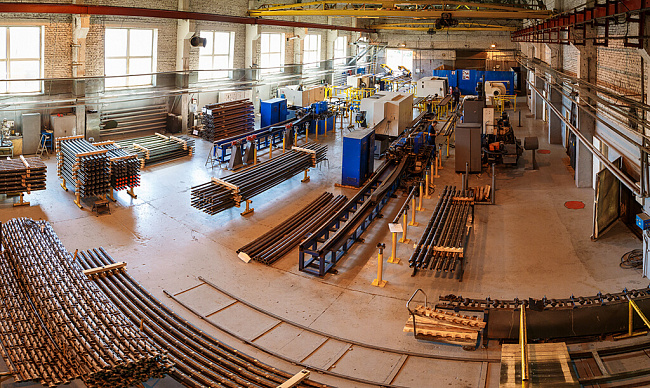

Production Facilities

One of the major factors of success and dynamic development of our company is its efficient and technological material, technical and production capabilities.

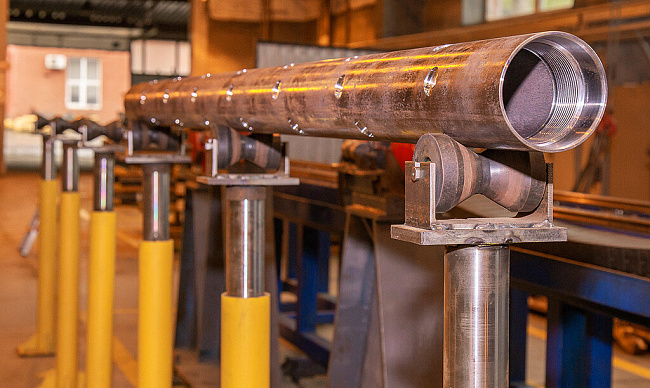

Manufacturing of perforation systems in the entire model range (diameters of 50-114 mm), shells for jet charges, accessories and tooling for charge manufacturing, fishing tools and other equipment for geophysical companies is done at JSC “SVMZ” in Samara.

This company combines three business units:

-

Manufacturing of jet charge shells;

-

Manufacturing of perforation systems;

-

Experimental manufacturing.

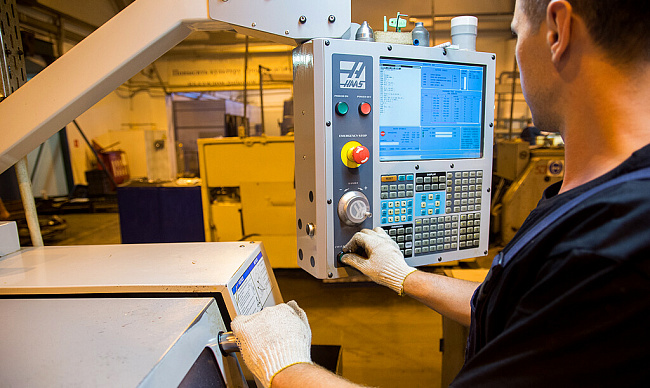

The total area of administrative, warehouse premises and production shopfloor is approx. 6000 square meters. The company uses the newest high-tech equipment. The machine fleet includes modern turning CNC machines from HAAS (USA), DOOSAN (Korea), four-coordinate programmable milling machines from DOOSAN, five-coordinate machining centers from HERMLE (Germany), and high-performance painting equipment.

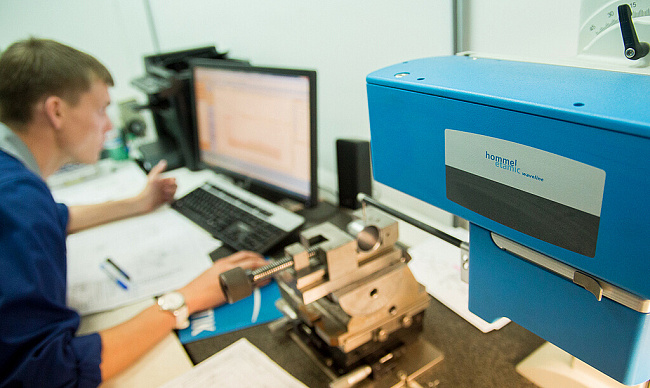

JSC “SVMZ” is the only manufacturer of perforating systems in the Russian Federation to be certified by the American Petroleum Institute to API Spec. Q1 (ISO/TS 29001). The company’s Quality management system ensures high quality of manufactured products and its compliance with international industrial standards.

Manufacturing of jet charges is performed on automated mass production lines that ensure quality and consistency of execution compliant with given technical parameters. The production capacity is up to 250,000 charges per month.

The production floor comprises the following sections:

-

Three shell charging sections;

-

Powder coating line;

-

Product release line;

-

Laser labeling line;

-

Finished goods vacuum packing section;

-

Detonation cord manufacturing section (continuous manufacturing);

-

Jet charge and detonating cord test facility;

-

Experimental shop for the manufacturing of prototypes and small serial production of perforation and blasting system components (percussion detonators, detonation transmission devices, etc.);

-

Incoming control laboratory for the incoming inspection of products and components.

Following evaluation of the experts, the production facilities of BVT are on the same level with, and sometimes surpass the best practices of manufacturing similar products.