Plug@Perf perforation technology

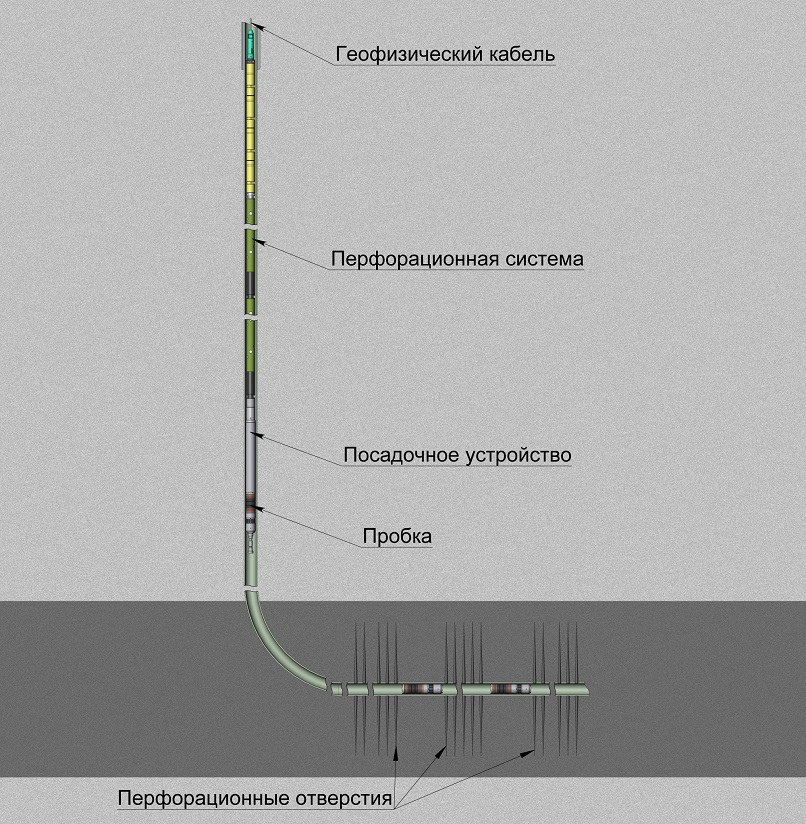

DownloadThe Plug&Perf technique is used for perforating on a wireline and coiled tubing. The assembly is transported on a wireline to the horizontal sections of wells by pumping.

The perforation by the Plug@Perf technology is designed for secondary drilling of several intervals with the installation of a plug during MSHF.

Operating principle

When working by the Plug@Perf technology, an assembly including up to 100 sections of the perforation system is run at once to open dissociated intervals by controlling the initiation by means of addressable electronic keys.

Advantages

The equipment used for perforation by the Plug@Perf technology provides real-time control of the process of positioning and initiation of each individual section of the PS or the landing nipple of the packer-plug.

The Plug@Perf perforation technology can be used for:

- wireline perforation (Ritrbomt)*;

- perforation on coiled tubing with a wireline.

*The assembly is delivered to the horizontal sections of the well on a wireline by pumping fluid with hydraulic fracturing pumps.

Advantages of Plug&Perf technology

- the equipment used for perforation allows real-time control of the positioning and initiation of each section of the perforating systems or the landing nipple of the packer-plug;

- increases operational safety;

- reduces the perforation time in multi-section systems.

The technology allows to run an assembly which includes up to a hundred sections of perfosystems during one trip. Sectional systems are used to open isolated intervals of wells by initiating shaped charges with addressable electronic keys.

The purpose of the Plug&Perf technology is the secondary drilling of several intervals of productive formations with the installation of a plug during multi-stage hydraulic fracturing.